Innovation, Quality and Accuracy

Process

HIGH SKILLED

PERFORMANCE

SKILLED

High

Tonnage

With a production capacity of up to 40 tonnes moulds, we develop and manufacture moulds for various sectors, such as the automotive, packaging and household appliances.

INNOVATION

High

Technology

QUALIFIED STAFF

High

Knowledge

MANAGEMENT SYSTEMS

Quality

and Innovation

A complete solution

1

Commercial

Able to answer any client, the sales staff assumes the commitment to review all requests received in order to offer the best possible solutions.

2

Project

Consisting of specialized professionals, the project team offers final product development services, mould design as well as filling and warping studies, ensuring the best way to produce, assemble and work with the mould.

3

Work programming, preparation and control

A multidisciplinary team defines strategies and methods aimed at reducing production times and optimizing the accomplishment of the work. The team follows up the manufacturing process to ensure the effectiveness of the defined strategies and the fulfilment of stipulated deadlines.

4

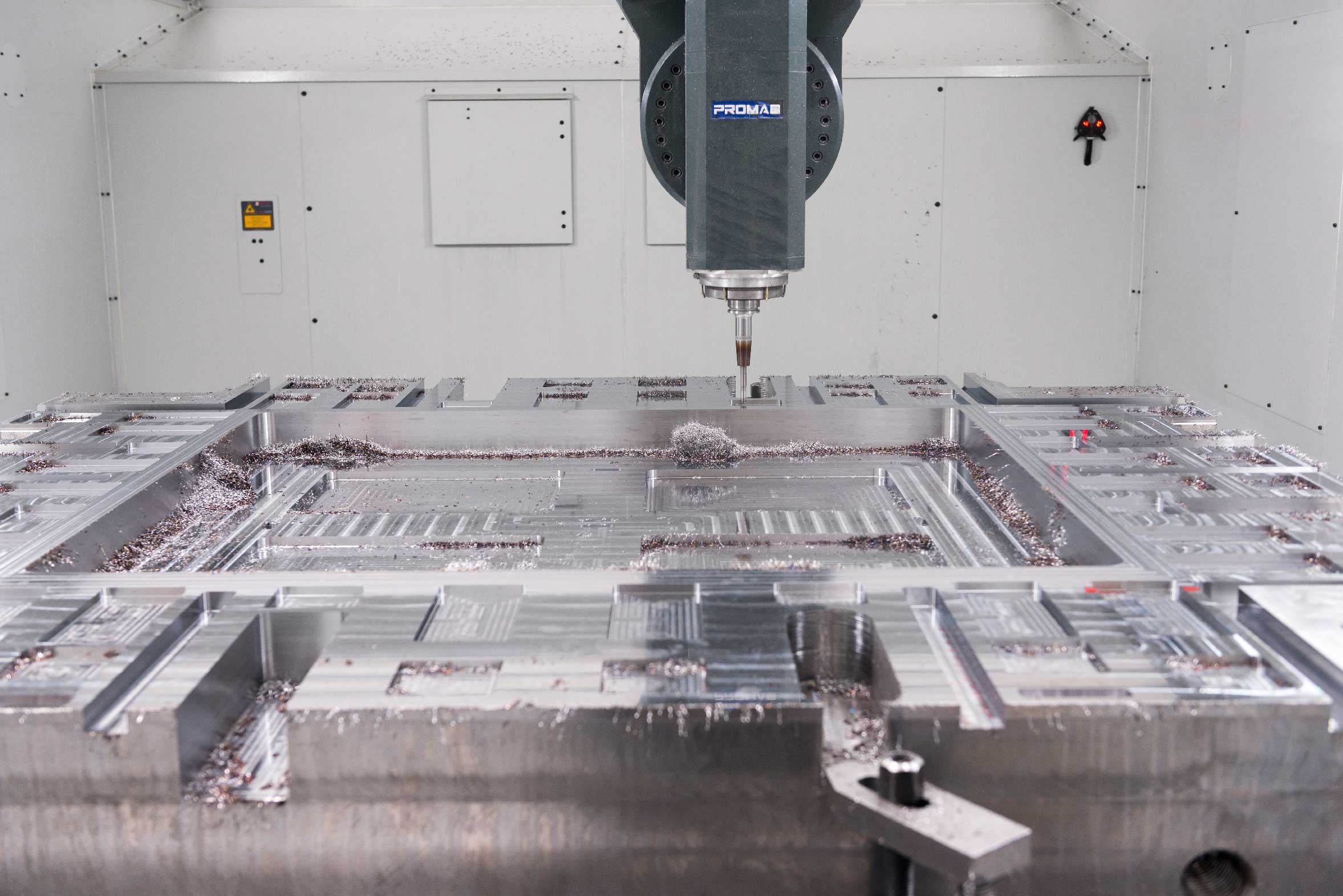

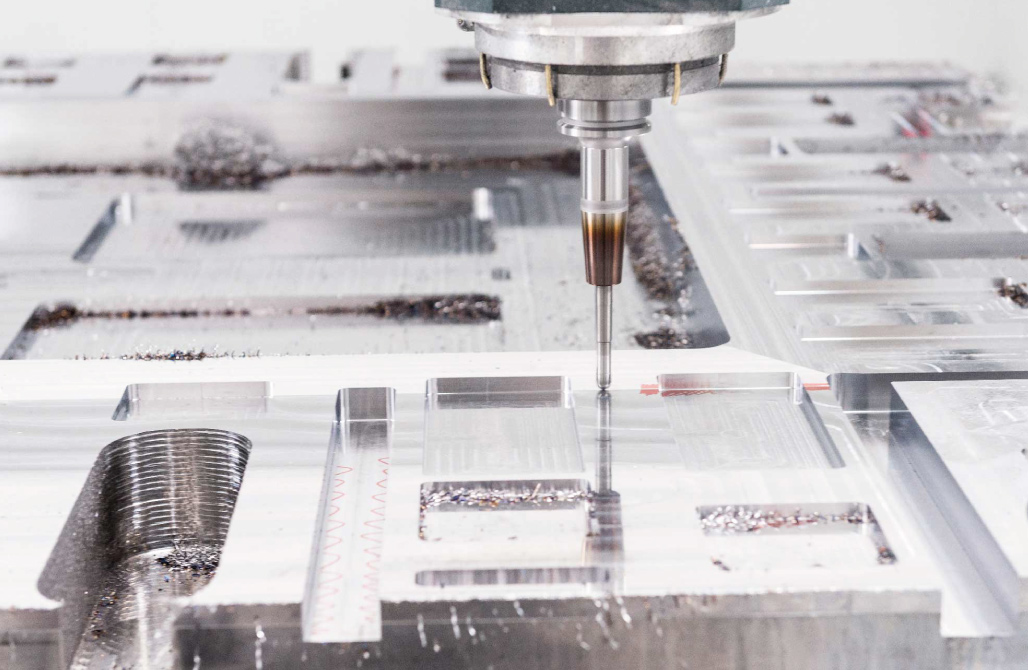

Manufacture

Equipped with the latest technologies, manufacturing covers areas such as drilling, 3 and 5 axes machining, erosion, conventional flatting and milling. Competent professionals innovate in the processes and selection of the best tools.

5

Process control

With three-dimensional verification equipment, the team conducts the necessary measurements to validate the work performed in the production. Dimensional control reports are issued and sent to the client whenever requested.

6

Assembly and finishing

The experience and professionalism of our bench operators guarantee the finishing of the mould according to the project carried out. With all the equipment available, including adjustment presses, works of greater complexity are finished with the desired quality.

7

Finished product quality control

All our moulds are rigorously tested in order to ensure not only their correct operation, but also to confirm that the results obtained in the plastic parts meet the needs and requirements of our customers.

8

After-sales service

The relationship with the customer goes beyond the shipment of the mould. At their request and when the complexity of the mould so requires, we send a team of our professionals who ensure the start of the production of plastic parts. We give quick and effective answers to any customer needs.